High-performance thermoplastics are ideally suited for reuse. With high-quality recyclates, ambitious CO2 reduction targets can be achieved quickly and cost-effectively. Convena Polymers offers PIR recyclates of relevant high-performance plastics such as PFA, ETFE, PVDF, PEEK and PPS for this purpose. For our CONvena® PPS RS-1340 GF40 as well as for our CONflon® ETFE Grades 7000 and 8000 we have now completed our carbon footprint analysis in cooperation with the SKZ (see PDFs below). These certify a CO2e saving compared to PPS GF40 virgin material of 88% for our CONvena® PPS RS-1340 GF40 and CO2 savings of around 97% for our CONflon® ETFE 7000 and 8000 grades compared to virgin ETFE.

With re-processing facilities in Europe, the USA and Japan, we have access at all times to high-quality and unmixed post-industrial production scrap for the re-processing of our CONflon® and CONvena® re-granulates such as PFA, ETFE, FEP, PVDF, PEEK and PPS.

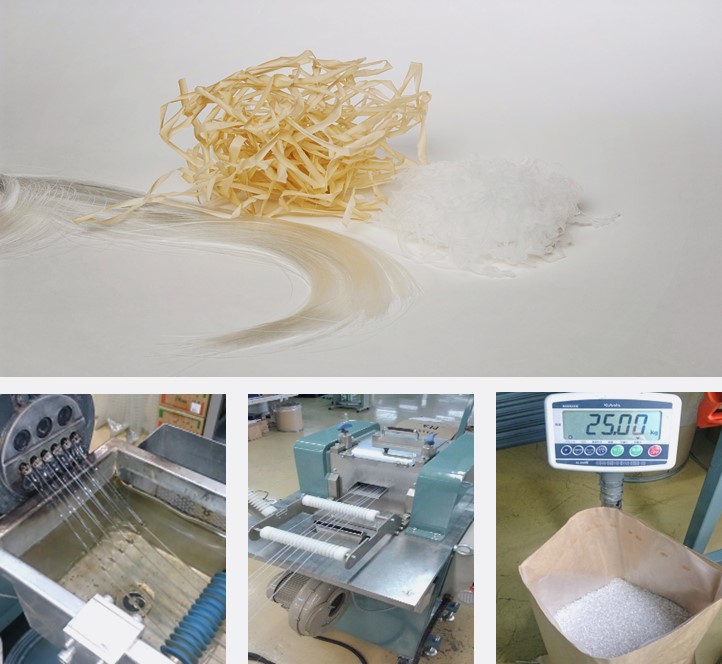

For the production of our, we regularly buy correctly sorted excess productions (sprues, mill feed, recycled materials, chippings, shavings, lumps, panel waste pieces, hard stock etc.).

Our main re-granulates include PFA, PFAm, ETFE and PVDF in diffferent grades and colors, PPS GF40 as well as PEEK semi-finished rods extruded from re-granulate.